Quinnox Implements Qinfinite Chaos Engineering to Help A Bottling Manufacturer

Our client is one of the largest and most complicated bottling and distribution operations in the world.

Read more

The client is a leading U.S.-based high-tech company, specializing in discrete manufacturing of telecommunication products, leveraged Qinfinite’s Auto Optimize to transform their IT operations, ensuring high availability and cost efficiency, leading to:

The company faced a significant challenge in managing its IT infrastructure. With an expanding product line and increasing data demands, their current infrastructure was stretched thin. An external assessment vendor had reviewed their system and recommended a drastic increase in infrastructure capacity—up to 60%—to handle projected future loads. This expansion was estimated to cost around $10 million, a hefty investment that would impact the company’s financial health.

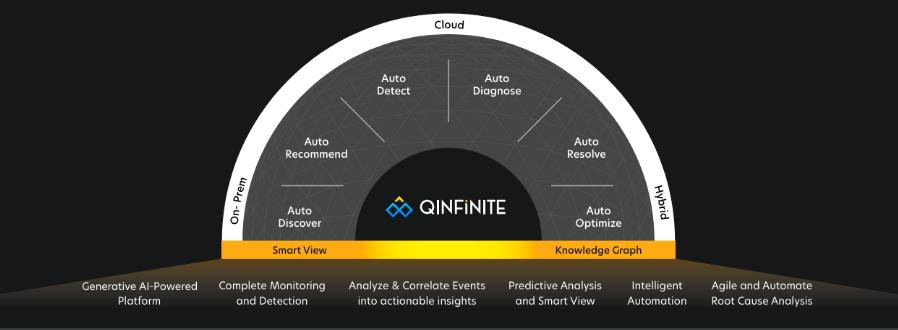

Quinnox stepped in with a recommendation to adopt a Qinfinite-powered solution. The proposed strategy was to maintain the base capacity on-premise for core operations and to leverage cloud solutions for scalable needs. This hybrid approach was designed to optimize costs while ensuring the flexibility to scale operations dynamically.

Implementation of Qinfinite Auto Optimize

Qinfinite’s Auto Optimize was configured to take a deep dive into the company’s infrastructure metrics. It leveraged the power of:

Auto Discovery & Knowledge Graph: To create a comprehensive digital twin of the IT ecosystem, mapping out all assets and their interdependencies.

Predictive Analytics: To understand usage patterns, seasonality, and business event impacts on IT demand.

Hybrid Infrastructure Management: Seamlessly integrating on-premise systems with cloud capabilities to ensure a balanced load.

The system was set to monitor real-time data continuously and use predictive analytics to forecast future capacity requirements. This allowed for automatic scaling of cloud resources during peak demand periods without human intervention, ensuring cost-effective resource management.

The implementation of Qinfinite’s predictive analytics capabilities led to transformative outcomes:

Cost Savings: The predictive scaling allowed the company to avoid the proposed $10 million expenditure, significantly reducing their operational costs.

High Availability: With real-time adjustments and predictive resource allocation, system availability remained at a stellar 99.999%, crucial for their 24/7 manufacturing operations.

Scalability and Flexibility: The hybrid model provided the flexibility to scale up resources during product launches and high-demand periods without permanent investment in infrastructure.

Our client is one of the largest and most complicated bottling and distribution operations in the world.

Read moreOur client is the largest independent mail, courier and logistics operator in the UK and Ireland

Read moreNorth America’s leading provider of integrated environmental solutions.

Read more